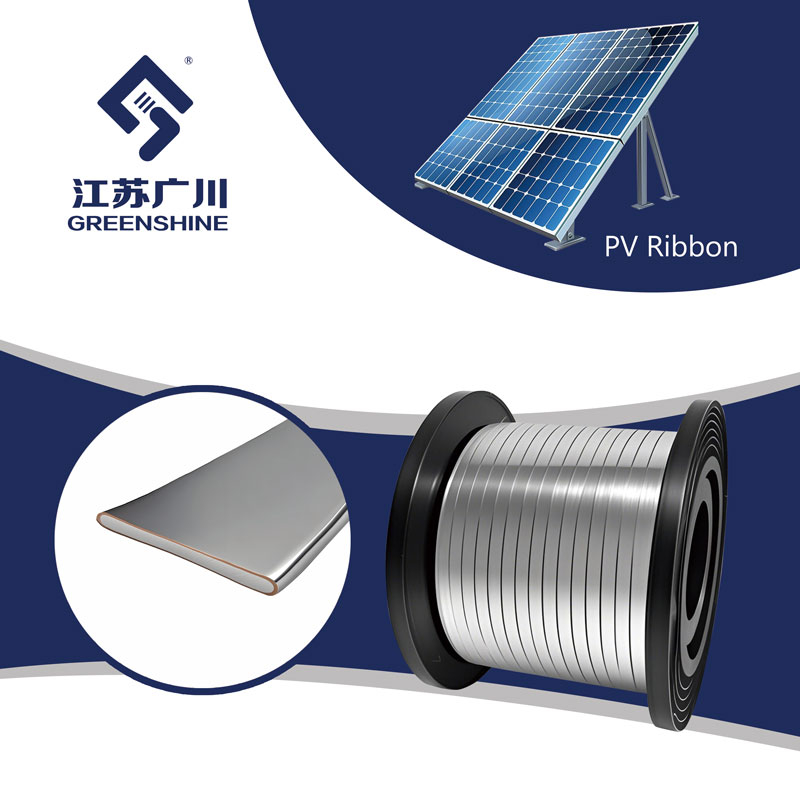

What is Copper Clad Aluminum PV Ribbon?

Against the backdrop of global carbon neutrality, the renewable energy industry is experiencing accelerated growth.

Photovoltaic (PV) power generation, as a cornerstone of clean energy transition, reached a record 400 GW of new installed capacity in 2023, a year-on-year increase of over 30% (IEA). PV modules, the core units of PV systems, determine service life and return on investment, with their cost and efficiency heavily influenced by materials.

Among these, PV ribbon functions as the “lifeline” for current conduction within modules. Although it only accounts for 5–8% of the module’s BOM cost, it influences 2–5% of overall efficiency. In recent years, Copper-Clad Aluminum (CCA) PV Ribbon has emerged as a cost-effective alternative to traditional copper ribbon, reaching a market size of 1.2 billion RMB in 2023 and expected to surpass 3 billion RMB (420–430 million USD)by 2025, with a CAGR of over 50%.

CCA PV Ribbon is produced via an integrated “composite–forming–plating” process, designed with a three-layer structure:

Base Layer (Aluminum): lightweight, cost-effective, density only one-third of copper.

Cladding Layer (Copper): ensures conductivity and solderability with solar cells.

Protective Layer (Tin Alloy): prevents oxidation and corrosion, ensuring long-term reliability.

This structure overcomes the drawbacks of full-copper ribbon (high cost, heavy weight) and pure aluminum ribbon (poor conductivity, difficult soldering), aligning with the PV industry’s pursuit of cost reduction and efficiency improvement.

Photovoltaic (PV) power generation, as a cornerstone of clean energy transition, reached a record 400 GW of new installed capacity in 2023, a year-on-year increase of over 30% (IEA). PV modules, the core units of PV systems, determine service life and return on investment, with their cost and efficiency heavily influenced by materials.

Among these, PV ribbon functions as the “lifeline” for current conduction within modules. Although it only accounts for 5–8% of the module’s BOM cost, it influences 2–5% of overall efficiency. In recent years, Copper-Clad Aluminum (CCA) PV Ribbon has emerged as a cost-effective alternative to traditional copper ribbon, reaching a market size of 1.2 billion RMB in 2023 and expected to surpass 3 billion RMB (420–430 million USD)by 2025, with a CAGR of over 50%.

CCA PV Ribbon is produced via an integrated “composite–forming–plating” process, designed with a three-layer structure:

Base Layer (Aluminum): lightweight, cost-effective, density only one-third of copper.

Cladding Layer (Copper): ensures conductivity and solderability with solar cells.

Protective Layer (Tin Alloy): prevents oxidation and corrosion, ensuring long-term reliability.

This structure overcomes the drawbacks of full-copper ribbon (high cost, heavy weight) and pure aluminum ribbon (poor conductivity, difficult soldering), aligning with the PV industry’s pursuit of cost reduction and efficiency improvement.